CademPVD is an intelligent software which designs process equipment quickly using minimum basic inputs. It is very user friendly and easy to. Agitators for minerals and metal industry offered, are robust designs with proven track records for a wide range of applications such as Crystallization, Dissolution, Extraction, Flotation, Leaching, Oxidation, Precipitation, Storage etc.

Fluid Properties

Scale of Agitation 1 is quite mild, 3 is normal, 6 is vigorous and 10 is violent.

- Scale of 1 to 2

- Characteristic of application requiring minimum fluid velocities to produce a flat but moving fluid batch surface. Scale 2 agitation will blend miscible fluids with specific gravity differences less than 0.1 and viscosity ratio of 100.

- Scale of 3 to 6

- Characteristic of fluid velocities in most chemical process industry's agitated batches. Scale 6 agitation will blend miscible fluids with specific gravity differences less than 0.6 and viscosity ratio of 10,000.

- Scale of 7 to 10

- Characteristic of applications requiring high fluid velocity agitated batches. Scale 10 agitation will blend miscible fluids with specific gravity differences less than 1.0 and viscosity ratio of 100,000.

Basic sizing calculations are based on square batch i.e. vessel diameter is equal to liquid level. For different geometries same process results are obtained by using appropriate number of impellers. Actual batch geometry is converted to square geometry, where Teq is the Equivalent diameter.

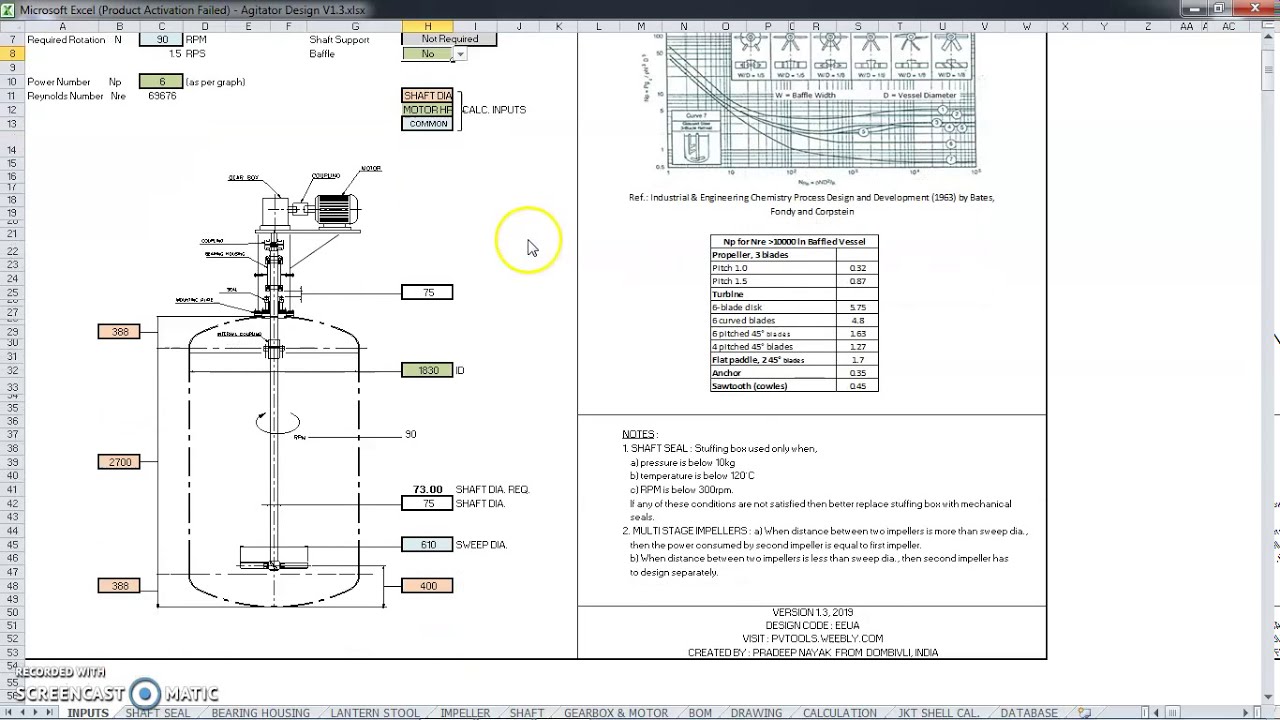

Power, P is calculated using definition of power number.

Agitator Blade Design

Assuming loading of 80%, motor power required